With the beginning of WWII American designers realized the Army lacked an adequate infantry weapon to counter advancements in tank technology.

During the 1930's a shoulder launched rocket prototype had been developed, with the great advantage of being recoilless, but its small HE warhead lacked effectiveness. During this same period anti-tank rifle grenade development, utilizing hollow charge technology, resulted in an effective grenade (M10) but its large size produced too much recoil to be fired without harm to both the rifle and shooter.

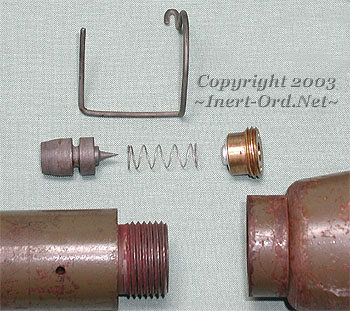

The idea of combining the M10 warhead with the rocket gave rise to the "2.36 inch Rocket Launcher".

(The diameter being that of the M10 grenade.)

Operation

Operation